Here in Fiji, we are having a rudder made. This deviates from the indication I described in a recent blog post when I said we were jury-rigging a rudder using stainless steel and fiberglass from salvaged boats. The first method appeals to my thrifty nature, but the method we are using is more permanent, and employs higher standards.

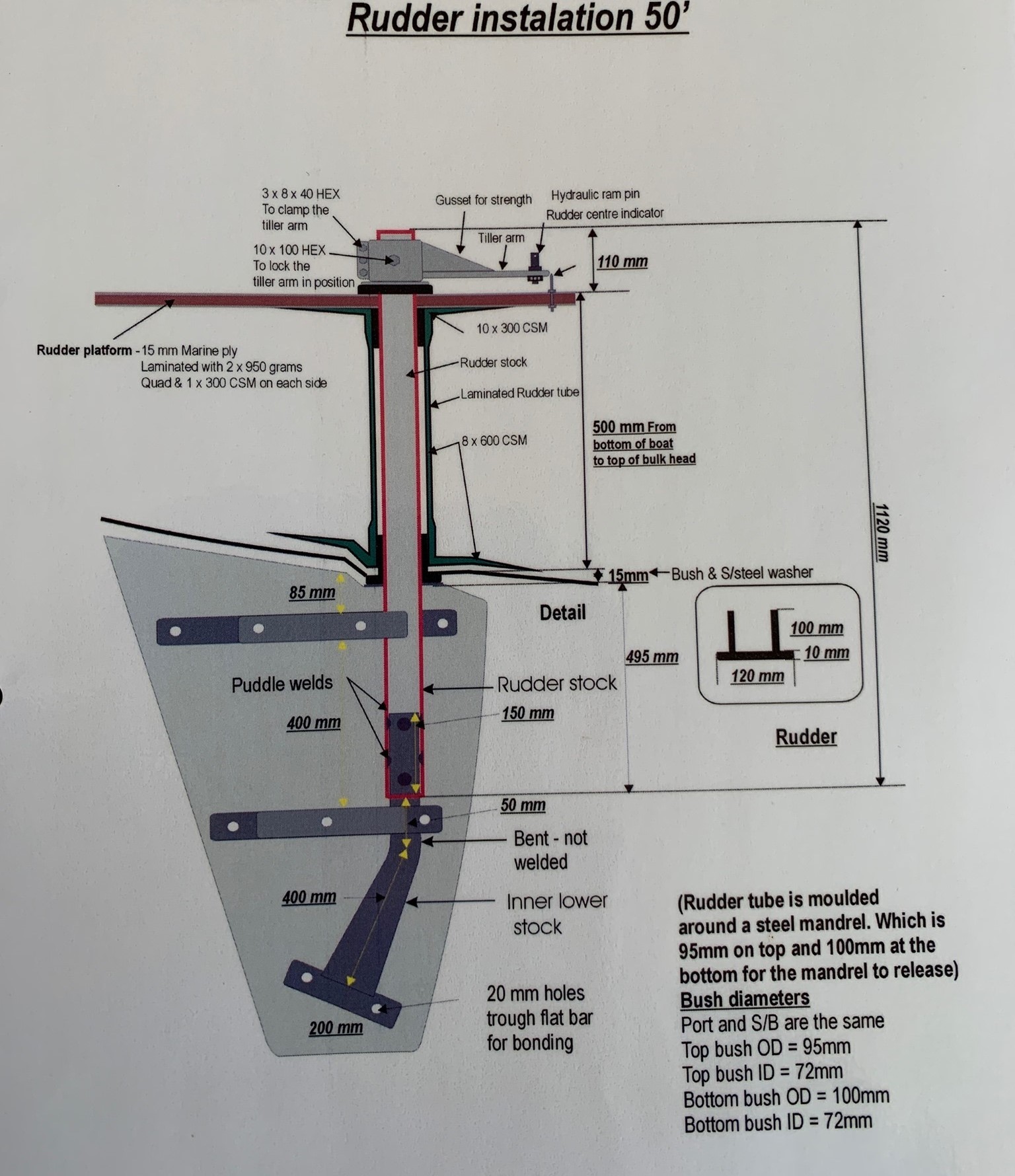

St Francis 50 rudder stock with schematic

Our previous rudder contained a stainless-steel component called a rudder stock. The schematic for our rudder appears below, next to a picture of one of our actual rudders.

We opened and inspected the rudders when we were in Trinidad. At the time, the welds in the rudder stock looked good. Obviously, something went wrong.

Losing a rudder

Maybe we hit something. Or, perhaps the rudder broke due to heavy weather or corrosion. As we sailed from New Zealand, the force on our rudder would have been tremendous. We saw gusts of 50 knot winds, and 5-meter waves for about 4 hours.

While losing a rudder might seem unusual and scary, the irony is that about 30 nautical miles before we reached our destination in Fiji, we responded to a call from a catamaran called SV Skedaddle; they had also lost a rudder. We talked to the captain for a bit, deployed our sea anchor and went to bed. About 8 hours later, we heard a Mayday call from SV Skedaddle.

Responding to a Mayday call from another catamaran

Overnight, SV Skedaddle had hit a reef. They had damaged their dagger boards, and had lost their second rudder. We responded to their Mayday call, along with a French-flagged boat that was headed to Nadi.

In the meantime, SV Skedaddle used their propellers to steer themselves off the reef. We motored a couple of hours through the night to meet them.

Towing SV Skeddadle

At sunrise, we gave SV Skedaddle a 150 ft line and towed them to Savusavu. We bought the line to tie ourselves into mangroves in case of a hurricane. The line is very thick and strong. You can see a short video of what that looked like below.

The Aftermath

Much could be said about the psychological results of losing a rudder, let alone two rudders. We were in the anchorage for days before we saw the couple on SV Skedaddle again. But, they are back on their feet, and on their way to getting their repairs sorted.

Our rudder repair

As for our rudder repairs, last week, Rick met a welder and someone who works with fiberglass. They determined that the work would begin following the long weekend. In the interim, we moved to a secure mooring to better position ourselves to remove a rudder.

Removing the rudder post and remains

On the weekend, Henry and I removed what remained of the rudder that we had lost. Nestled in next to our generator, with the sun beating in, removing the rudder collar was hot work.

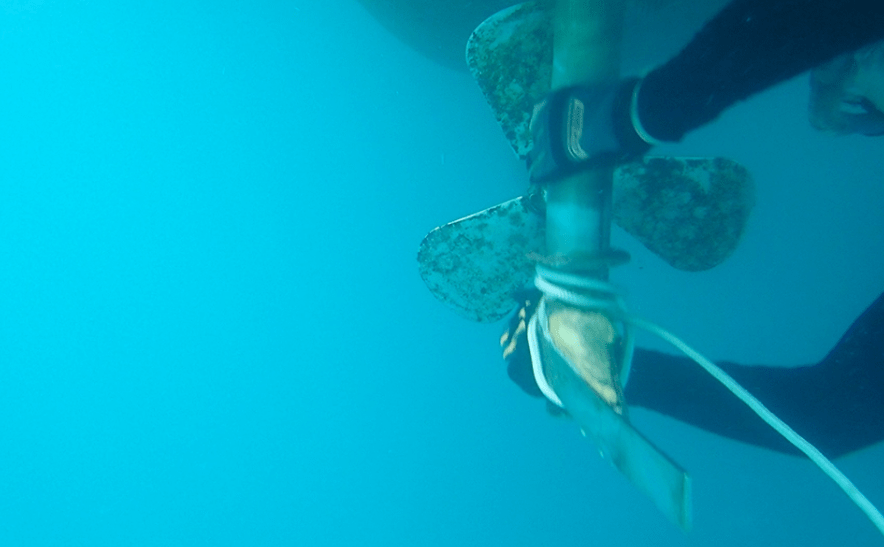

After the rudder collar was removed, we were ready to drop the port rudder post and what remained of the rudder. That was a fun job as it meant being underwater. You can see that we tied a rope to the rudder for security. The rudder post would have cost thousands of dollars to replace if we had lost it underwater.

Removing our good rudder to make a mold

The next day, was just as hot, but we had gained some confidence. We removed our good rudder on the starboard side. The starboard rudder will be used to make a mold for our new, port rudder.

We used the topping lift line and our boom extension to lower our rudders into the water and to raise them onto our back transom. It’s as though our boat comes with its own crane.

Stainless steel loops: a Cool add-on

You might notice that we have a stainless-steel loop welded to the top of each of our rudder posts. The loops help to minimize the risk of losing a rudder during the removal process. They also help guide the rudder in and out of the rudder tube. The loop is not centered on the rudder post; Rick had them made to be offset to accommodate our emergency tiller arm.

Welding in Fiji

Here is a picture of Ritesh who welded a new rudder stock for our port rudder, along with a close-up of the rudder stock. We supplied some of the 1/4 inch stainless plate that you see. We had bought the plates in Savannah, Georgia as they had once been the stainless mounts of our old Fischer Panda generator.

Up next, will be for someone to build a mold for the rudder, make a fiberglass shell, and integrate the stainless steel welding work with foam. The port rudder will be complete early next week. Then, we will head to the Lau Island group.

You guys never cease to amaze me well done

LikeLike

Thanks Mark!

LikeLike

Gratulerer med forsinket bursdag til Cecilie!

LikeLike

O.MY.GOSH This makes my head spin. Is this something that you have to learn on the fly, or is there a prep class called “what to do when it all goes t–s up?”

LikeLike

Haha! I document the solutions, not so much the stress. Rick comes from a family on people who can. I come from a house that had minimal tools. So, I must admit, that I enjoy using a socket wrench because it is novel to me.

I think I could do a lot better in terms of managing stress. The loss of the rudder nearly did me in terms of how to manage feelings of vulnerability at sea.

Rick was very measured when he dealt with the Mayday call. I think that helped everyone’s headspace.

I vowed that I would an umbrella drink when we reached shore to ‘find the fun’ so to speak. I had a virgin pina colada but they were out of pineapple juice so they used orange juice instead and I didn’t mind a bit. So glad to get off that crazy ride from NZ to Fiji.

LikeLike