The woodwork on our boat had been on our mind for years; 2025 was the year we decided upon a contractor, arranged a place to haul-out, rented short-term accommodations, and set our plans in motion.

Defining Project Scope

We have lived and sailed on SV Aphrodite for ten years. Her floors and cabinetry bore the scars of raising four children afloat. But, the flooring has always been a sore point. In fact, I believe our first reaction after purchasing our boat was “Good Lord! What happened to the flooring?” That was in March 2015.

Flooring

As the ink dried on our sales agreement, the previous owner pasted a classroom-brown linoleum floor into the central living area, directly onto the original teak and holly. We think he meant well. But, with wear, the floor yellowed like a nicotine stain; its only redeeming quality was that it was a talking point; so distractingly ugly that visitors would notice the floor before they saw any dirt.

The rub was that, to Rick, floors matter — a lot. Rick’s dad, Alfred, founded Centennial Floors in Calgary. The seeds of Rick’s entrepreneurial spirit and work ethic took root as he watched and learned to install floors with precision. Flooring was his family’s lifeblood and a source of pride.

For ten years, Rick sailed our boat, stuffing thoughts about nice flooring in the dark recesses of his mind. “We’ll get it replaced one day,” he said.

Cabinetry

The cabinetry had pockmarks from toys run amok. The varnish on our freezer had been worn away by dozens of swimsuit-clad kids who had, at one time or another, climbed onto our freezer top and huddled together to watch a movie, while adults talked in the cockpit. It was in need of repair.

Improvements

Beyond the flooring and cabinetry, we saw other areas for improvement on our boat. Admittedly, some of these items will be of interest to St. Francis catamaran owners more so than anyone else. But as St. Francis 50 owners, we wanted:

- a completely level, polished saloon table: ours had warped in the excessive heat when we went away for a few months in Georgia. We had it repaired professionally, but it was a bit of a botched job.

- better access under the nav desk: we wanted another cupboard made so we could reach wires.

- a better housing for the mirrors in the bedrooms: (frames or having the mirrors inset) for a more finished look.

- cleaner, more-organized nav desk area: over time, the nav instruments had started to look crowded.

- improved maneuverability in the cockpit: we wanted to replace the existing fiberglass table with a folding teak table.

- teak holders for kayak and upright paddleboard paddles: we wanted to replace our temporary plywood holders.

- a new Corian countertop: ours was cracked when we bought it, and the repairs we had done in Florida were largely ineffective.

- teak step at the base of our new, comfortable, helm seat.

- removable hinges: to allow us to remove the doors and cabinet doors for cleaning and access.

- wooden hatch covers with mosquito netting throughout: to replace the OceanAir PVC hatch trim, and roller blinds.

We borrowed the idea for the wooden hatch covers after visiting a friend’s boat.

Finding a Woodworking Contractor in Southeast Asia

For as long as we’ve had children, Rick has wanted to take our kids to Southeast Asia, and he had heard that this would be a good area to refinish our woodwork. Teak can be easily sourced and other sailors spoke highly of skilled craftsmen in Indonesia, Malaysia and Thailand.

Meeting Mr. Chong of Eastbay Teakdecks – Marine Carpentry in Malaysia

Last year, we went to Pangkor Marina in Lumut, Malaysia, with hopes of having the woodwork done. However, the marina did not have the in-house talent, and we would have had to source the job to outside contractors. That is where we first met Mr. Chong of Eastbay Teakdecks – Marine Carpentry. After driving to our boat from Penang, he shook Rick’s hand and immediately had his eyes on the work. He was curious about our boat. He came into our cockpit and we moved our sliding glass door, whose wheels struggled with the weight of the door, and he said, “I will fix this.” But, at that point, we were a long way from project start.

Communicating Expectations

To communicate expectations, Rick and I went around the boat, cataloguing every nick and issue we wanted repaired. We used painter’s tape to highlight an issue, using terms like “PFC” for Port Forward Cabin, and “PAC” for Port Aft Cabin, and then we numbered the issues within the area.

In all, around Christmas time 2024, I made 150 short videos, each about 20 seconds long. I explained the problem but not the solution. Our reasoning was that Mr. Chong’s team would have more experience in the area of resolving issues with woodwork.

The video below shows a sample of three short videos that we made to identify and communicate the woodwork issues on our boat.

Deciding Where to Do The Woodwork

Where to do the work was an important consideration. Rick and Mr. Chong probably met ten times in the past year to discuss the project. Mr. Chong’s company, Eastbay Teakdecks, has a team of craftsmen in Penang and Langkawi.

Haul-out or Stay at a Marina?

Between those two locations, we had to decide if we wanted to have the work done in the water or out of the water. After looking at some marinas together, Rick and Mr. Chong found roadblocks as some marinas have rules about the type of work that can be done. Some marinas do not want laundry hanging on the lifelines, let alone dusty projects tainting their image as hangouts for high-end yachts.

In the end, it made sense to haul-out. We had some out-of-the-water projects in mind, and we wanted to apply anti-fouling paint before sailing to South Africa. Our boat has a wider beam (width) than many boats. This narrows the possibilities for places that can haul us out.

Decision Made

After sailing back from Thailand, we had made our decision. And, the woodwork project was shaping up to look like this:

Contractor: Mr. Chong, Eastbay Teakdecks

Location: Langkawi, Malaysia, hauling-out at Lunas Shipyard (formerly known as Boustead), where we could also remove our anti-fouling and repaint

Finding Accommodations in Kuah, Langkawi

And, that is how we came to be renting a homestay in Kuah, Langkawi, away from the dust on our boat. The house is furnished, and within walking distance of amenities. Lunas Shipyard is quite isolated but we can reach it from the house within a 12-minute drive. Using Grab, it costs us about $8 CAD round-trip.

Preparing for the Woodwork

While Mr. Chong ordered the wood, glue, Epifanes varnish and other supplies to do the job, we purchased hardware, and prepared for the arrival of the woodworkers by clearing the boat of items and fixtures.

Hardware Purchases for the Woodwork

The purchase of hardware involved lots of measuring and communicating with suppliers. Communication was tricky because marine-quality (316) stainless steel is not readily available in Malaysia.

Chinese companies sold the products we needed, but the information they sent seemed confusing. Because we literally do not speak the same language, sometimes we questioned quantities and even whether a “left hinge” for us, was actually a “right hinge” to the Chinese supplier.

Hardware purchases included:

- Allen head bolts, nuts and washers for the hatches: we decided to through bolt the Lewmar metal hatch frames. (approximately 200 of each, including spares)

- custom stainless backing plates for the hatches: they look like thin rulers and distribute the force of the bolts, which are holding the hatches in place. We had these made by a welder in Langkawi.

- Phillips head wood screws for the hinges, and wooden window trims

- 85 left hinges (includes 15 spare hinges)

- 130 right hinges (includes 15 spare hinges)

- new hinges for our freezer

- new hinges for the cockpit table

Items we Removed to Prepare for the Woodwork

The items we removed to allow the woodwork to begin include:

- all of the overhead hatches and re-bedded them to ensure they were watertight

- all the fixtures: handrails and wall sockets

- our Corian countertop and arranged for a new one to be made

- our nav instruments to allow a new panel to be made

- our saloon dining table

- our laundry hutch that is under the dining table

- all of our belongings (except for our tools), and moved them to the house in Kuah

- appliances: oven, stovetop, fridge, microwave, and Miele washing machine

Eastbay Marine Arrives: Ready for Action

To give you the sense of how far we took this refit, here is a picture of our galley before we embarked on this project.

Mr. Chong’s team arrived ready for action. They removed all of the doors, and cupboard doors to refinish offsite at their workshop.

What a lot of trust to put into a contractor.

Seeing our Corian countertop lying in jagged shards was a shock.

The extent that we were tackling the repairs was unnerving. Eastbay built a template for our Corian countertop and we sent it to a manufacturer that we had been communicating with for the past year (and which I will discuss in a separate blog post).

Walking through the cockpit, our saloon and galley were dull and had been sanded. In just a few days, our boat had turned from a nice boat into a project boat, and we were paying money for this to happen.

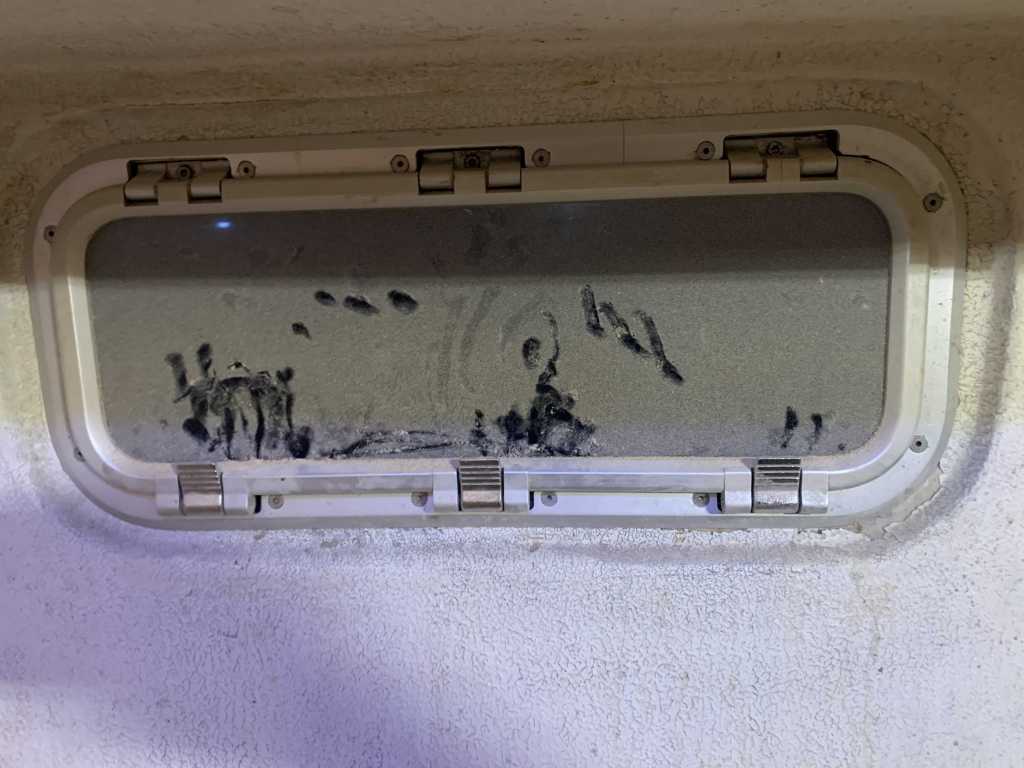

Memories Etched into Our Woodwork

With several woodworkers on our boat, I realized that the wear on our wood held fond memories. Check out the worn patch at the top of our galley stairs, discolored by the feet of my children who came to the top of the stairs to the galley and asked, “What are you making?” or “How long before supper?”

At one point, I discussed keeping the discolored piece of linoleum. But, I am content with saving a picture. Having children is all about letting go, and the woodwork is just a small part of accepting that we can share memories and grow to build new ones.

At one point, I asked:

“Rick, are you sure they know what they’re doing?” This is more than I had thought they‘d be doing.”

Meanwhile, Mr. Chong’s men ate their lunch in our cockpit, away from their tools, with a view of our dismembered galley countertop. I needn’t have worried.

Progress in Photos

It’s hard to capture the full project in photos but I shall try by providing before, mid-project and nearing-the-end photos of the nav/saloon area, starboard, and port woodwork.

Saloon and Nav Area Woodwork in Progress

This video shows Eastbay’s work and materials in the early days of the woodwork project. You can see that, in places, the linoleum flooring has not yet been fully removed. In the saloon, the original teak and holly — the flooring that was installed by St. Francis Marine is revealed — a brief appearance, just before it was removed.

Beginning of Project

Mid-Project

A month in, Henry and Rick planned our nav station to accommodate our instrument panels, and Eastbay made a new cupboard behind where Henry is standing in the photo. The cupboard looks like it has always been there.

Three Months Later: After the First Coat of Varnish

Port Woodwork (Galley)

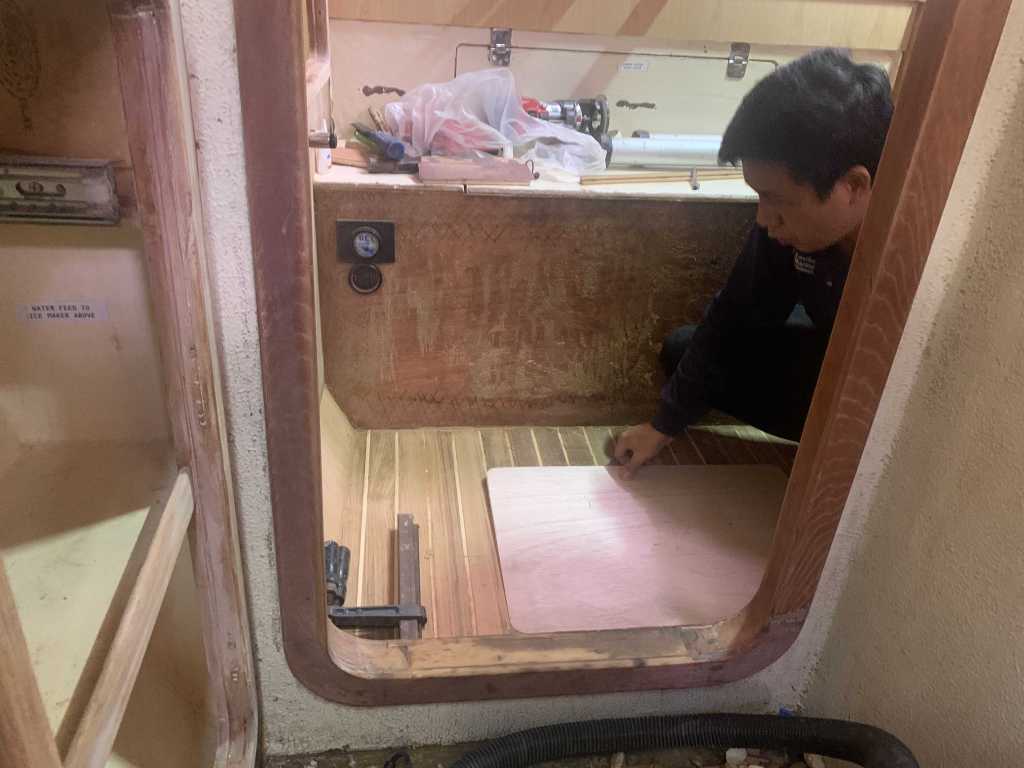

Here is a progression of photos that show what our galley flooring looked like before, and what it is looking like now, as we are nearing the end of the project.

Port Woodwork (berths)

Below, Chin is installing the flooring in the Port Aft Cabin, which is Paul’s bedroom.

If you watched the video where I described the work needed, the little shelf will look familiar; it is a close cousin to the shelf that appears in the segment where I describe “Port Aft Cabin 9.”

Starboard Progress in Photos

Here is what the flooring looked like during installation on the starboard side.

Taping off the Entire Boat: Preparing for Varnish Video

Applying the varnish was a bit of wizardry that involved taping off our entire boat. This is what it looked like on the starboard side.

Nearing Project End

Mr. Chong’s team works hard and they are very precise. I can only recall two other contractors where I have felt completely at ease – knowing that they know what they are doing, and so I don’t have to worry about someone cutting corners. From start to finish, this project will have taken five months. There is more to come. Eastbay is applying varnish and soon it will look a lot different than the photos show. I am looking forward to seeing what’s in store.

Related page: About Our Boat

Pin it

If you enjoyed this story, you can save it to your own Pinterest board using the image below. Thanks for reading and following our journey.