For years, I was a person who did not enjoy measuring things.

If I could compare and confirm my measurements with a documented source, like the measurements of my Miele W1 washing machine, I would be fine.

But if I had to make other measurements, like the clearance under my television set or the space between our swim ladder supports, my eyes would narrow, and my mouth would feel the tension of a drawstring purse.

This year I needed to step up my game.

Our boat is on hardstands at Lunas Shipyard in Langkawi, Malaysia. Two companies were working remotely on our boat projects in Kuala Lumpur. Neither of these companies have ever visited our boat. We are on an island, an hour’s flight away from KL.

We were spending meaningful sums of money. Accurate measurements mattered. Brother Lim was relying on input from us for our re-upholstery projects, and Lalang Resources needed dimensions and precise angles to build us a replacement Corian countertop.

As I mentioned in my recent woodwork blog post, our old Corian countertop was cracked in several places when we bought the boat. We had it repaired in 2015 but the cracks were still visible and difficult to clean.

The measurement requirements of Brother Lim began slowly, and then a few curves were thrown in. By the time Lalang needed dimensions for our outboard countertop my stress level was at a fever pitch. This blog post focuses on the outboard countertop. Fortunately, the inboard countertop was more straightforward.

Group A and Group B Thinkers

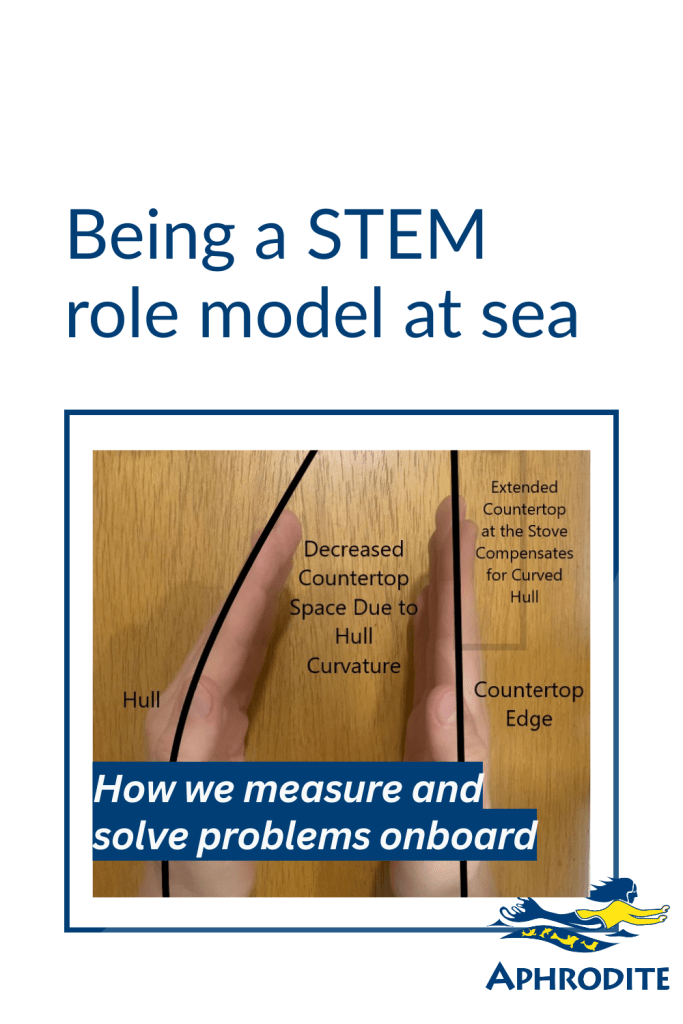

I think I can separate my readership quickly with this visual:

Cup your hands in front of you to make a bowl shape. Now, along your left hand, plan a countertop and backsplash to fit this shape.

Some people (we will call ourselves Group A) will throw their hands in the air and say “this is not for me.” But I challenge you to stay with the idea. What if you were it; your countertop required you alone to provide this information.

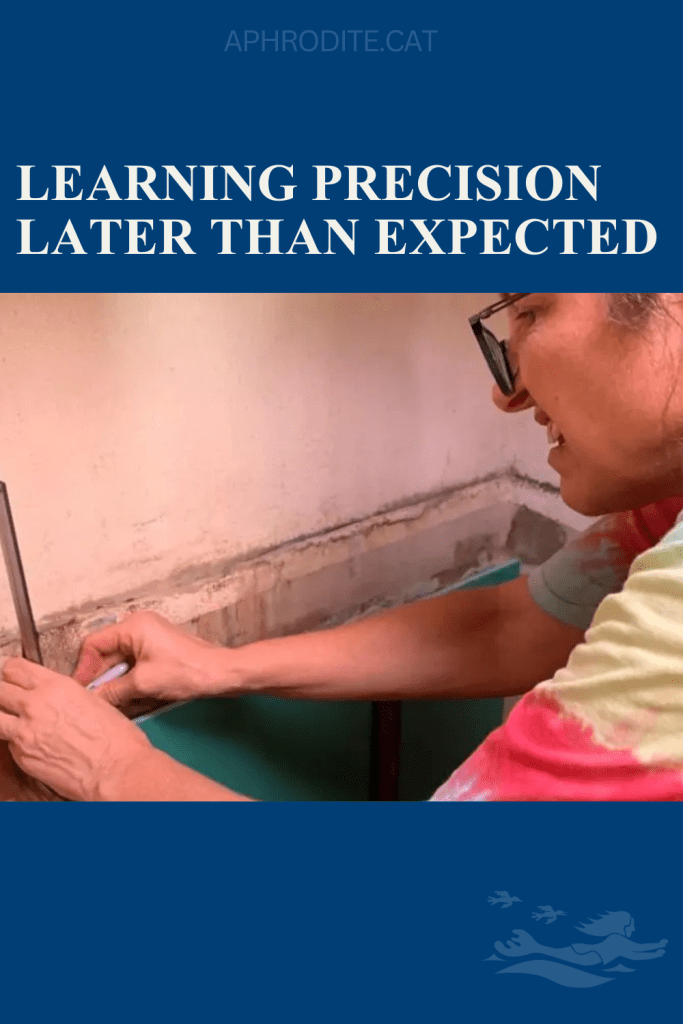

And, by the way, my 14-year-old daughter Karen (pictured) is looking to you as a role model. She likes science and is wondering if STEM subjects are for her.

Lorraine, Self Appointed to Lead Group A

Group A – I posit the challenge is ours for the taking. We can learn to join the other group of people (Group B) that say, “it can be done”.

2025 was the year I learned it wasn’t that I didn’t like measuring, it was that I didn’t know how to precisely measure something. I am referring to length, width, depth, slope – the whole nine yards.

What I didn’t realize earlier that I do now, is that measurement is a skill.

Rick, Nominated to Lead Group B

I’m going to put Rick temporarily in charge of Group B, until we find a willing candidate. Rick and his group are comfortable with the challenge of communicating how to build a countertop. They have learned the skills needed to take accurate measurements. Further, their mathematical abilities allow them to communicate about angles with confidence.

Group Bs are not wizards. Their observation skills have been honed by trial and error, in labs, or with hands on activities where someone has made suggestions to improve their accuracy. They likely heard things like, “Hey! Stand straight in front of that ruler and tell me exactly what number you see” or “Pay attention to the influence of your dominant eye”. In an academic setting, lab results provided feedback as to what areas to improve. Grade results provided further reinforcement.

Group As – we might have lacked the same feedback cycles. But, there is no need to pigeon hole ourselves as “right brained” or “arts student”.

First Challenge: Taking Countertop Measurements for a Galley in a Curved Hull

Group A: This section will take us as far as measuring a countertop, allowing for a curved hull. Had I known that I needed to stand right in front of the item to be measured, I wouldn’t have seen the variance that made me think I was seeing double.

But, Rick was out of town. The countertop contractor needed the dimensions of our countertop. I needed to communicate the curve. A woodworker named Chin stepped in and made some measurements.

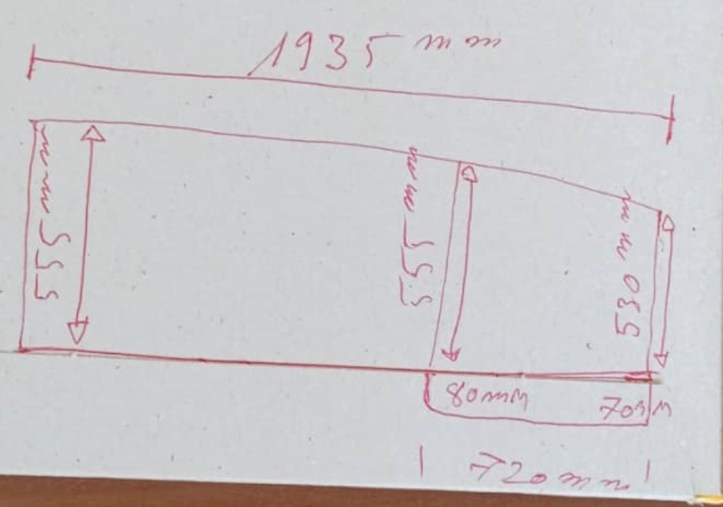

Chin took a few measurements and sent Rick a sketch.

With Rick in KL, Chin’s note signaled (to me) there would be no escaping this issue.

My First Lab

Over the phone, Rick asked me to take measurements of our countertop depth five times, using seven different data points. You can see the seven data points where I labeled the hull (back of our countertop) from A to G.

Karen and I measured the depth from each letter on the hull to the edge of the countertop. I thought I was going to lose my mind. At some angles, I could easily see another ¼ inch. Then, like magic, the depth snapped back and was on the inch mark. Was I holding the ruler absolutely straight? Was the wall straight?

Karen and I did our best. My back ached. The sun went down but still we continued. Every measurement put us closer to completion. As time went on, we felt more confident. Though we were tired, we opted to do a sixth pass because we didn’t trust our first set of measurements.

Confirming our Results

We sent our results to Rick.

Rick used our data to calculate the average measurements and draw some conclusions.

Average measurements of our galley countertop

A = 16.5

B = 16.33

C = 14.67

D = 14.83

E = 16

F = 15.83

G = 15.67

Well, that’s weird. The countertop clearly juts out at the stove. Yet, the average measurement at the far left of the countertop shows the countertop depth around the garbage cupboard (A) to be slightly larger than at the stove (G).

I’ve always assumed that the countertop extension for the stove was there to allow space for our oven. But by measuring the countertop we confirmed what Chin had said. “The back of the countertop is not flat”; the curvature affects the amount of usable countertop space. Without the countertop extension, our countertop would look like an ill-planned, vanishing point.

How a Curved Hull Affects Countertop Space: A Demonstration

I’ll demonstrate this topic using Betty’s hands who, incidentally, has applied for STEM programs at university in Canada to start next fall.

The curvature of our hull means our countertop is not as wide as it would be if the hull was parallel to the countertop.

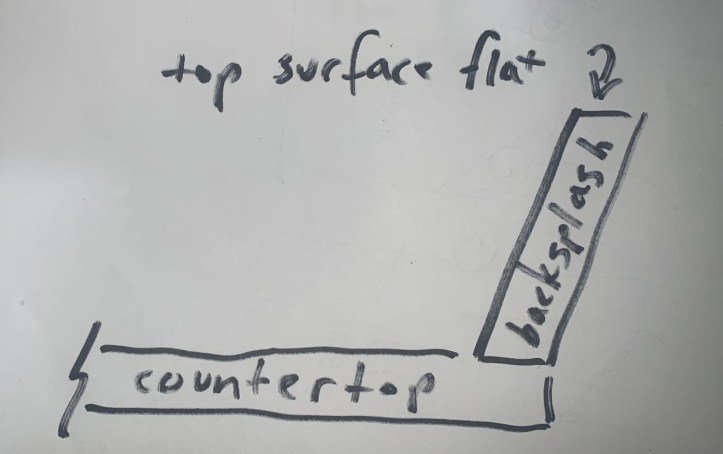

Second Challenge: Calculating the Angle for the Backsplash in our Galley

Calculating the backsplash in our galley relies on trigonometry.

The name itself begins with “tri” (sounds like “try”) so that’s a start.

Right?

“The very name trigonometry derives from the Greek words for ‘triangle’ (trigōnon) and ‘measurement’ (metron).”

History of Mathematics, Carl B. Boyer & Uta Merzbach

So, two simple terms, “triangle” and “measurement” form a bit of wizardry that somehow escaped my recollection of high school. If I can measure my countertop 42 times, surely, I can manage measuring the 3 sides of a triangle. These concepts were created thousands of years ago, and shared by different cultures. So, in a sense, measuring the angles of our backsplash provides a connection through time to people who also solved real-world problems

Group Bs will lead this exercise.

Eastbay Teakdecks had already built templates for our inboard and outboard galley countertops. We had sent the templates to Lalang Resources by courier.

Making Woodblocks for Solid Communication

In talking with Lalang Resources, we didn’t need to provide another template. Instead, Rick needed to provide key data points. Specifically, he needed a way to communicate the angles at the corners of our countertop and the angles for our backsplash. As we’ve established, the countertop was not square. So, the angles could not be assumed; they had to be measured and communicated to Lalang Resources.

Group As, I know what you are thinking. “Good thing he knew how to measure the angles…Next.” But, again, stay with me. The angle calculation is not hard. Greeks who participated in naked athletics may have done these very sorts of calculations. We can do this.

A backsplash on land is likely 90°. Our hull shape requires just a bit “extra”, which is shown with the colorful theta (θ) symbol.

Calculating the Angle of Our Outboard Backsplash

The horizontal measurement is the measurement of space between the hull and an imaginary vertical backsplash. In our case, the horizontal offset is 16 mm. The vertical measurement is the finished height of our backsplash (105 mm). And, we are calculating the unknown θ angle (which is just a little angle (to bring us closer to the full angle of our backsplash.

Calculating our backsplash angle is a three-step process. First, we calculate the tangent.

1. Calculate the Tangent

The tangent is the ratio between the opposite (the 16 mm horizontal offset) and the adjacent (the vertical 105 mm measurement).

So, with our values:

2. Solve for θ using Arctan

First compute the fraction:

Now take the arctan:

So the angle of the tangent, θ = 8.66°.

We are almost done.

3. Calculating the full angle from the countertop

To make the backsplash so that it fits against the hull, the angle we need to communicate to Lalang resources is the full angle from the countertop to the hull. From the diagram, we can see that the full angle is:

90° + 8.66° = 98.66°

So, 98.66°.

Yay us, we’ve calculated the angle of the outboard backsplash.

How to Demonstrate the Angles to Lalang Resources?

For solid communication, Rick created five woodblocks.

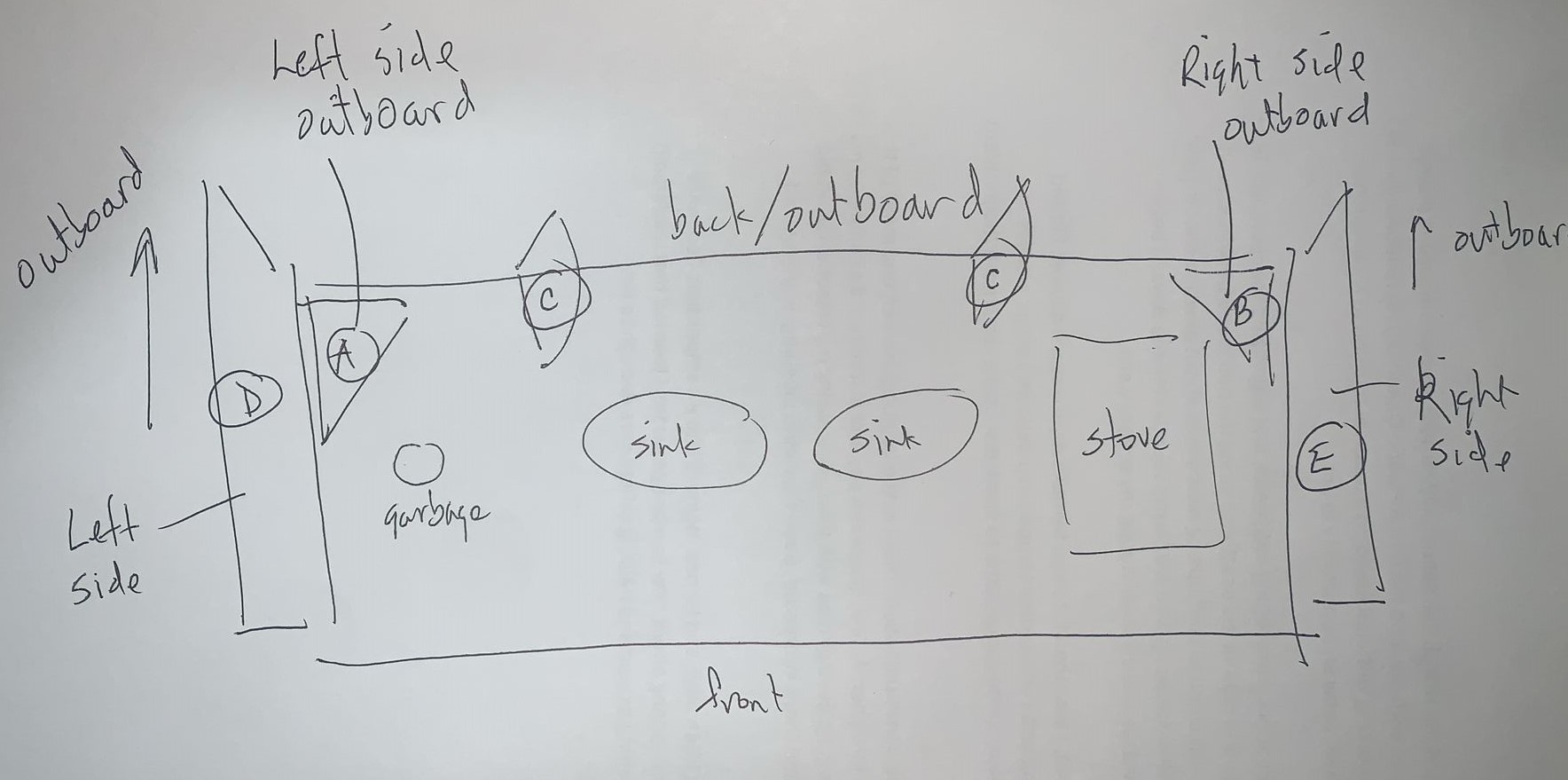

The purpose of the woodblocks was to demonstrate angles for our countertop and backsplash:

- Countertop Angles: A shows the angle at the left corner of our countertop; B shows the angle at the right corner of the countertop

- Backsplash angles: C shows the angle of the back/outboard backsplash (which we calculated to be 98.66°), and D and E show the angles needed for each end of the left and right backsplashes.

Rick’s Plan for the Woodblocks

He sent the five woodblocks to Lalang in KL by courier. When Lalang wanted confirmation as to where to arrange the blocks, Rick marked up a photo they had sent of the template.

Lalang Places the Woodblocks on Our Countertop Template

A Video from Lalang Resources Shows Mutual Understanding

Lalang Resources responded by sending a video. Their video showed a clear understanding of the angles involved in completing our countertop.

Interestingly, the template is laid-out on our Corian countertop block. We chose the color Lava Rock, which is slightly lighter than the countertop we had previously. The Corian in the video is devoid of gloss but that comes later after sanding.

Here’s where I leave you. I am not claiming to teach math, but hopefully, I will provide enough information to someone else who is tackling an angled backsplash on the curved hull of their boat.

Our new countertop has been made and is under wraps in a hangar at Lunas Shipyard. We have yet to open it. I am looking forward to the big shiny reveal.

Pin it

If you enjoyed this story, you can save it to your own Pinterest board using one of the images below. Thanks for reading and following our journey.

Related post: Measuring for a Miele W1 Washing Machine